PUWER and LOLER Explained: How These Key Regulations Work Together to Ensure Workplace Safety

In today’s workplaces, especially in industrial and commercial settings, safety isn’t just a legal rule it’s key to running things smoothly and keeping employees safe and healthy. With machinery, tools, and heavy lifting being integral to many workplaces, the risk of accidents is ever-present. According to the Health and Safety Executive (HSE), a significant number of workplace injuries each year are linked to improper use of equipment and inadequate planning of lifting operations.

This is where PUWER and LOLER come in, two essential sets of regulations under the Health and Safety at Work Act 1974. These laws were established to help employers systematically manage risks associated with work equipment and lifting operations. PUWER covers all kinds of work equipment used in the workplace, while LOLER deals specifically with lifting equipment and lifting operations.

Understanding how these two regulations function, and how they complement each other, is essential for any business that values safety, compliance, and productivity.

What is PUWER? A Framework for Equipment Safety

PUWER stands for the Provision and Use of Work Equipment Regulations 1998. It sets out requirements for any equipment used by employees at work, from hand tools and ladders to large-scale machinery.

PUWER aims to ensure that all work equipment is safe, well-maintained, and used only by those who are trained and competent.

Key Requirements of PUWER:

- Equipment Suitability: All equipment must be appropriate for the task, taking into account the working environment and potential hazards.

- Maintenance and Inspection: Regular, documented inspections are required to identify wear, defects, or mechanical issues before they lead to failure.

- Operator Competence: Employees must receive proper training on how to use equipment safely and efficiently.

- Risk Assessment and Controls: Employers must evaluate potential risks and implement control measures such as emergency stop functions, guarding mechanisms, and safe operational protocols.

- Ergonomics and Accessibility: Equipment should be designed or adapted for safe, ergonomic use.

What is LOLER? Ensuring Safe Lifting Practices

LOLER stands for the Lifting Operations and Lifting Equipment Regulations 1998. It applies to any lifting equipment or accessories used to lift or lower loads, including cranes, hoists, forklifts, chains, slings, and lifting frames.

LOLER is designed to ensure that lifting operations are properly planned, supervised, and carried out by competent persons. It emphasizes the prevention of accidents that could occur during lifting tasks.

Key Requirements of LOLER:

- Thorough Planning: All lifting operations must be carefully planned in advance. This includes choosing the right equipment, assessing environmental conditions, and defining safe lifting paths.

- Supervision and Execution: Operations must be supervised by a qualified individual, ensuring safety protocols are followed throughout.

- Routine Inspections: Lifting equipment must be subjected to thorough examinations by a competent person at prescribed intervals (usually every 6 or 12 months).

- Certification and Records: Employers must maintain up-to-date records of inspections, servicing, and certifications for all lifting gear.

- Qualified Personnel: Everyone involved in the lifting operation, from operators to riggers, must be trained and competent.

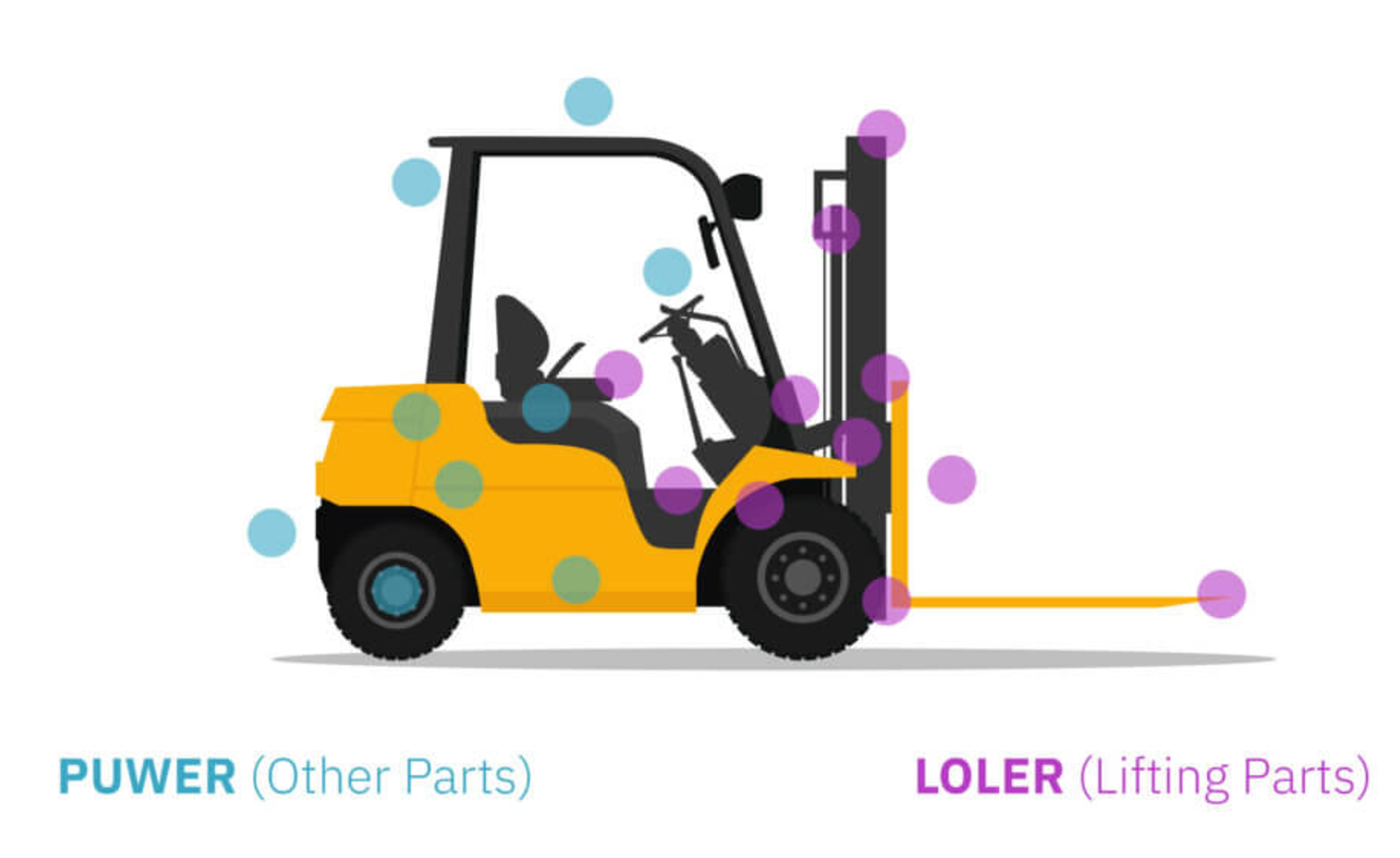

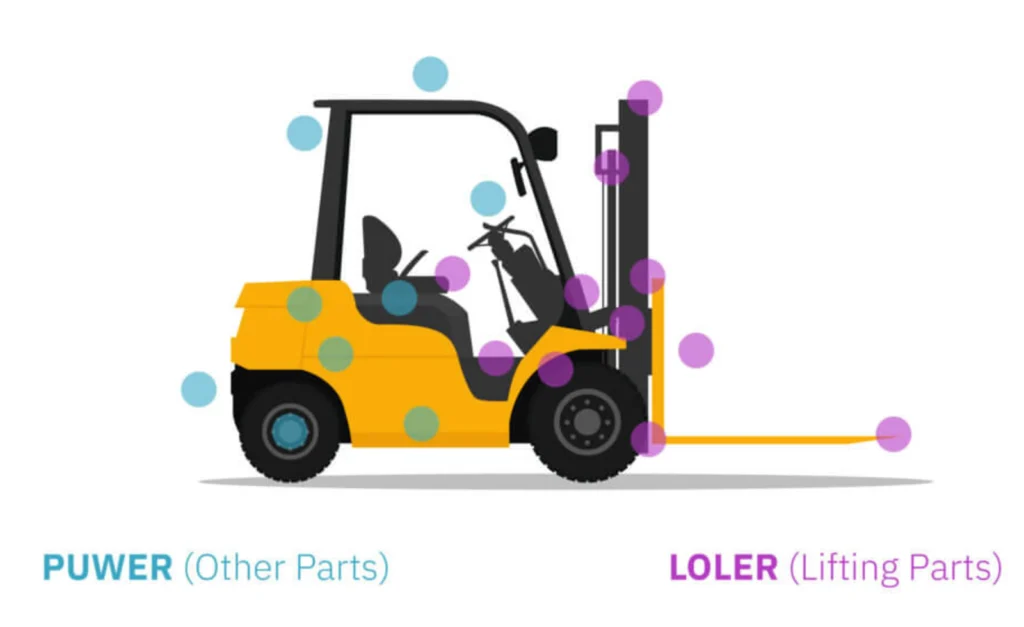

PUWER vs LOLER: Complementary, Not Competitive

It’s important to understand that PUWER and LOLER are not competing regulations, they are complementary. Both are designed to manage workplace risks but focus on different aspects.

How They Interact:

- PUWER applies to all work equipment, including lifting gear.

- LOLER applies specifically to lifting equipment and operations, adding additional requirements for safety planning, supervision, and inspection.

This means that lifting equipment must comply with both PUWER and LOLER. PUWER ensures general safety, usability, and maintenance of the equipment, while LOLER ensures that lifting tasks are safe and well-managed.

Meeting Your Obligations Under PUWER and LOLER

For employers, compliance with PUWER and LOLER is not just about avoiding penalties, it’s about safeguarding lives and sustaining business operations.

Employer Responsibilities Include:

- Ensuring Equipment Suitability: Match equipment to its intended use under PUWER guidelines.

- Scheduling LOLER Inspections: Ensure that lifting gear is examined by a competent person every 6 or 12 months (depending on use).

- Keeping Comprehensive Records: Maintain detailed logs of equipment servicing, inspections, certifications, and operator training.

- Employing Competent Staff: Only allow qualified and trained personnel to operate equipment or perform lifting tasks.

- Performing Unified Risk Assessments: Combine PUWER and LOLER requirements into a single, coherent safety strategy.

Failing to meet these responsibilities can result in serious consequences including fines, legal claims, operational downtime, and reputational damage.

Practical Tips to Stay Compliant and Safe

Here are some proven best practices for staying compliant with both PUWER and LOLER:

- Create a Preventive Maintenance Schedule

Use a digital calendar or asset management system to automate PUWER checklists. - Book LOLER Inspections in Advance

Partner with an HSE-approved competent person or inspection body to avoid lapses. - Maintain Centralized Documentation

Use cloud-based systems to store inspection reports, servicing logs, operator licenses, and certificates for easy access during audits. - Conduct Regular Staff Training

Offer induction and refresher courses on equipment use and safe lifting operations. - Label Equipment Clearly

Mark machinery with inspection dates, load limits, and operational warnings. - Appoint a Compliance Officer

Designate someone responsible for managing PUWER and LOLER obligations across the workplace.

Conclusion

Safety is a Joint Effort – PUWER and LOLER in Sync

Workplace safety is not a one-time event, it’s a continuous, shared responsibility. PUWER and LOLER, when applied together, form a powerful legal and operational framework for ensuring that workers stay safe, machinery remains reliable, and lifting operations are free from preventable hazards.